We develop and manufacture single-purpose machines, control stations , or upgrade your existing production equipment. We focus on close cooperation with our customers and hold a high service level.

We integrate systems for 2D and 3D visual inspection and machine vision. We supply sophisticated robotic solutions, which can save significant costs.

We provide design services, design and manufacture fixtures and individual components.

Our customers are both major domestic and foreign companies, especially in the manufacturing industry.

Lines

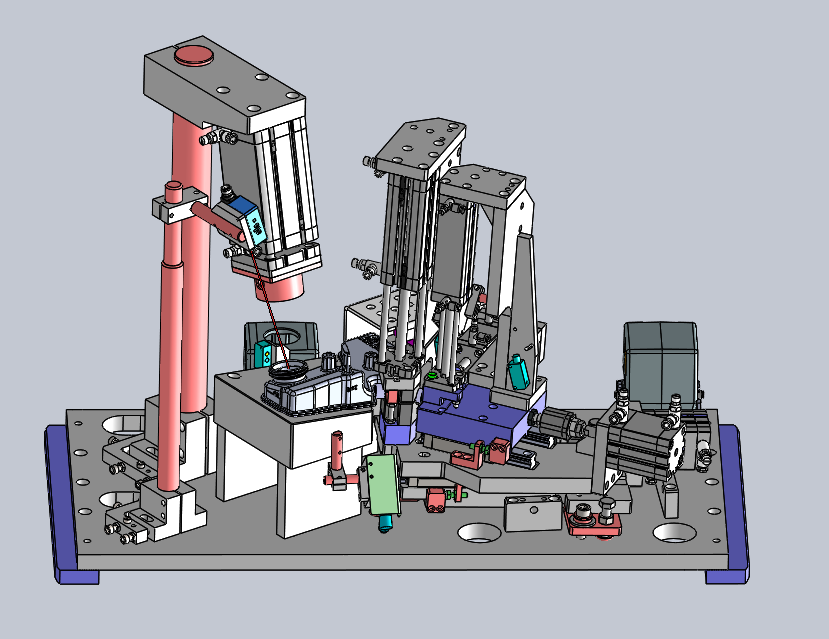

We specialize in the development, design and manufacture of single-purpose machines and automated production lines that are not mass-produced anywhere in the world. Our machines are used for various manufacturing operations such as assembly, pressing, testing, measuring, forming, inspection or electrical testing. We also carry out upgrades and optimizations of existing equipment. We work with Siemens control systems. We place maximum emphasis on reliability, which is also contributed by the fact that we put only quality and proven components from leading domestic and foreign manufacturers (BALUFF, FESTO, HIWIN, KEYENCE, LENZE, LINTECH, RAVEO, SICK, SIEMENS, SMC) into our machines.

Design and development

Own CAD studio

Are you missing a spare part and it is no longer on the market?

Delivery time is too long?

Don’t have the necessary drawing documentation ?

3D parametric solid modelling: 3D PDF Publishing (3D PDF output)

Creation of 2D and 3D drawings in a program compatible not only with AutoCAD

Output formats ( STEP, IGES, SAT, STL, DWG, DXF, etc… )

We will measure, draw and produce from design to assembly in your company. We provide a fast service, ensuring prompt delivery, including finishing transport to your company. If you are interested in creating 2D, 3D drawings, we are fully compatible with all formats known today.

For measurements we use mainly precise Mitutoyo digital gauges

Data collection, online production monitoring

A group of applications designed to visualize and monitor data on production machines and lines. The system enables the collection of data from various data sources, which are then stored in central data repositories (typically databases). The monitoring systems are designed as a client-server architecture that allows for data validation, range checking, defining value dependencies, and processing automated and scheduled tasks.

Robotization

The integration of industrial robots into manufacturing operations is an increasingly widespread phenomenon. The increasing versatility and decreasing cost of robots is already enabling their use in an increasingly wide range of activities where it is neither efficient nor realistic to purchase large numbers of single-purpose machines. The possibilities for deploying robots are thus expanding significantly.

We can supply you with a robot that exactly imitates the sequence of movements of a human worker, which it is then able to repeat incessantly. Thanks to this tirelessness of industrial robots, companies can significantly increase their production with minimal waste. Greater involvement of robots could thus reduce the understaffing that our industry suffers from.

Service and advice

Of course, we provide warranty and post-warranty service both for our own supplied commodities and for similar systems from other manufacturers.

CNC machining, metal fabrication

– metal fabrication on CNC machines, turning, milling, grinding, laser burning

– machining of all available materials (stainless steel, aluminium alloys, plastics, etc.)

– design activities according to customer requirements